Poorly Done Story Essay

Essay, Academic, Study Poorly Done Story Essay

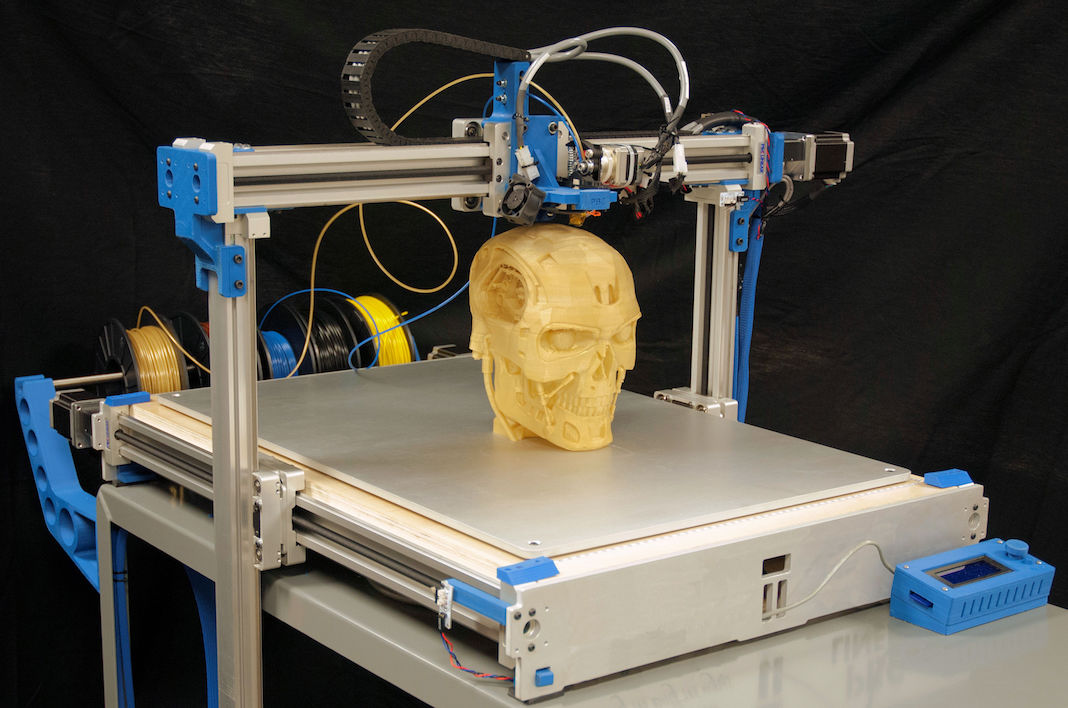

The additive 3D printing process is responsible for creating a three-dimensional product - this is when, during the manufacture of an object, layers of material are superimposed on each other, from bottom to top, until a copy of the form in the drawing is obtained.

2022-12-03, by ,

#Under $500 || #3D Print || #Review ||

This is how plastics are printed. And photopolymer printing works on stereolithography (SLA) technology: under the influence of a laser emitter, photopolymers harden. In addition to plastic and photopolymer resins, Best 3d printer under 500 work with metal clay and metal powder.

Next, the program converts the model into instructions for the extruder and uploads it to the printer, which starts printing the product. How to program a 3D printer

Brief instructions for setting up the printer:

Depends on the quality of the media, printer and end product. Often home printers do not accurately convey the shape and color of an object. Plastic products need additional processing: sometimes they are printed with burrs and defects, and almost always with a ribbed surface - Wiki for example.

There are several ways to treat the surface - not all are suitable for home use: